On October 21, Degalen hosted a successful event at the Coca-Cola Canlubang plant, titled “Enhancing Reliability & Uptime in the Food & Beverage Industry.” With a hybrid setup, the event connected maintenance personnel and managers from various Luzon plants, allowing both in-person and virtual participation.

This event was part of Degalen’s Luzon initiative, which aligns with our core belief in customer-centricity.

We are dedicated to helping our customers enhance reliability and maximize uptime in their operations.

By providing comprehensive after-sales service and access to the latest technologies, we empower our customers to optimize their maintenance practices and improve plant performance.

The event featured in-depth discussions on Schaeffler’s comprehensive Industrial Lifetime Solutions (ILS) portfolio, spanning from bearings to smart maintenance tools.

Key Discussions and Highlights:

- Bearing 101: The event kicked off with a dedicated bearing knowledge session provided participants with essential insights into bearing maintenance, helping to elevate their team’s understanding and improve their operational practices.

- Schaeffler Industrial Lifetime Solutions (ILS): Schaeffler’s complete ILS portfolio was introduced, focusing on predictive maintenance tools like smart lubrication systems and Optime—positioned as the future of condition monitoring. Optime empowers plants with real-time data, enabling proactive maintenance to reduce downtime and enhance equipment reliability.

- Bearings for F&B Plants: An overview of the bearings commonly used in the Food & Beverage industry, including both standard and linear bearings.

- Smart Maintenance Tools: Attendees had the chance to see Schaeffler’s advanced smart maintenance tools in action, including the Laser Alignment System, The Iductor and the MFT 3.5 Generator, all designed to improve accuracy and operational efficiency in plant maintenance.

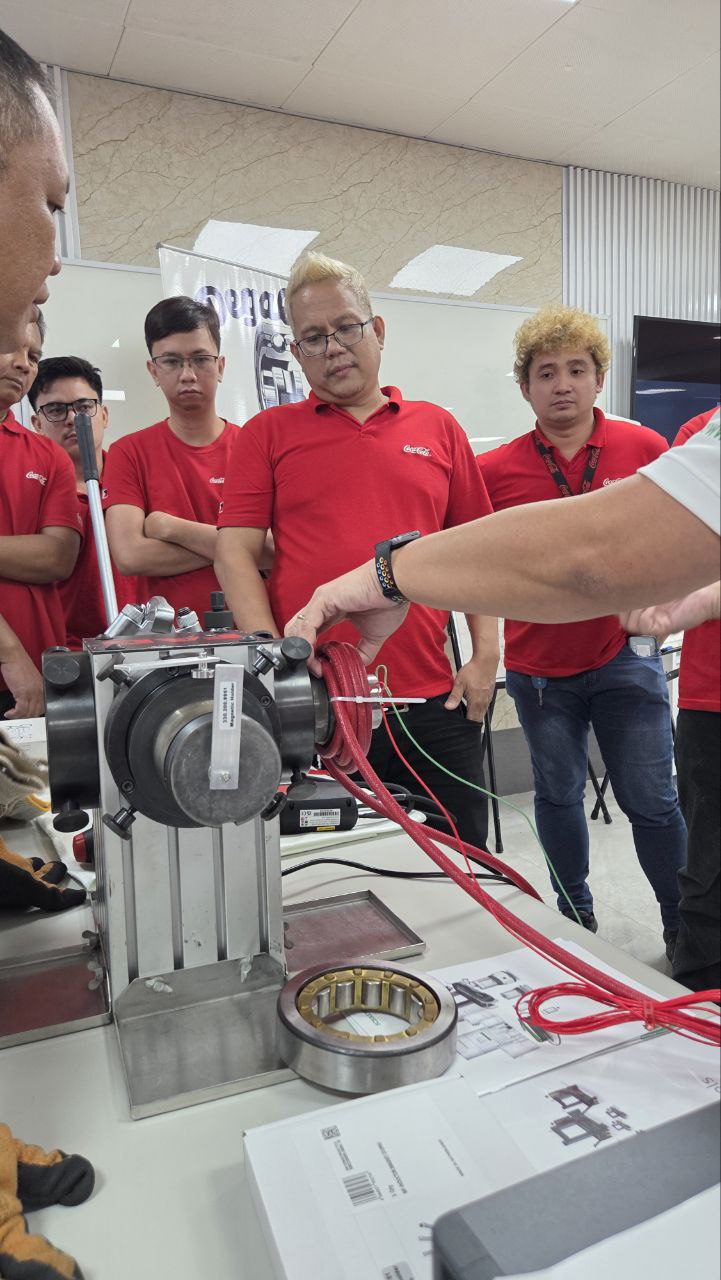

Hands-On Demonstrations:

The event featured hands-on demonstrations of Schaeffler’s latest smart maintenance technologies. This gave participants practical exposure to these tools, allowing them to see how these tools in action.

Commitment to After-Sales Service:

This event was a key part of Degalen’s after-sales service initiative, centered on our customer-centric approach. Through free training, detailed discussions, and hands-on demonstrations, we equip our customers with the tools and knowledge they need to improve their operations and maintain long-term reliability.